List of Engineering Tools:

- 1. Camera

- 2. 3D Connexion SpaceMouse

- 3. Multiple Monitors

- 4. Gaming Mouse

- 5. Mechanics Mirror

- 6. LED Torch

- 7. Calipers

- 8. Rulers

- 9. Gorilla Tape

- 10. Sticky Tac

- 11. Smartphone

- 12. Stroboscope

- 13. Thermal Camera

- 14. Anatomical Measuring

- 15. Multimeter

- 16. Load Cell

- 17. Pens

- 18. Calculator

- 19. 3D Printer

- 20. Laser Scanner

- 21. Knee Pads

- 22. Paper

- 23. Thinkpad

1. Camera

One of the best engineering tools is a camera.

Why?

Taking pictures or videos of what you’re working on gives you a LOT of information you can refer back to.

For example, say you’ve designed a product and it’s been shipped to the customer.

However, the customer realises a part is broken.

The customer is angry and blaming you for the broken part – but you know full well that everything was fine when it was shipped.

Having image proof of the product before it was shipped can get you out of trouble and prove accountability.

In a similar way, if you work in Quality Engineering, pictures can be used to record manufacturing defects and on what date they occurred.

Another reason a camera is a great engineering tool is if you are more hands-on and build equipment.

If you work in assembling parts (both on and off site), filming yourself stripping a tricky assembly is useful as the video can be played back to make sure each part goes back in the right order.

This can save lots of time and costly mistakes.

If another engineer has to deal with the same equipment, the video could be shared and more time saved.

A video, or even a simple picture, is a lot easier to grasp than having lots of text to read.

Filming mechanisms can help show other engineers how something works. It can also be used to find out why something isn’t working correctly.

If you deal with fast moving equipment, such as conveyors, a slow motion feature can be very useful.

In the plastic forming industry, a slow motion video helps to see how the plastic is forming and if it can be improved.

Another use for a camera is that it can help you model 3D objects in CAD quickly.

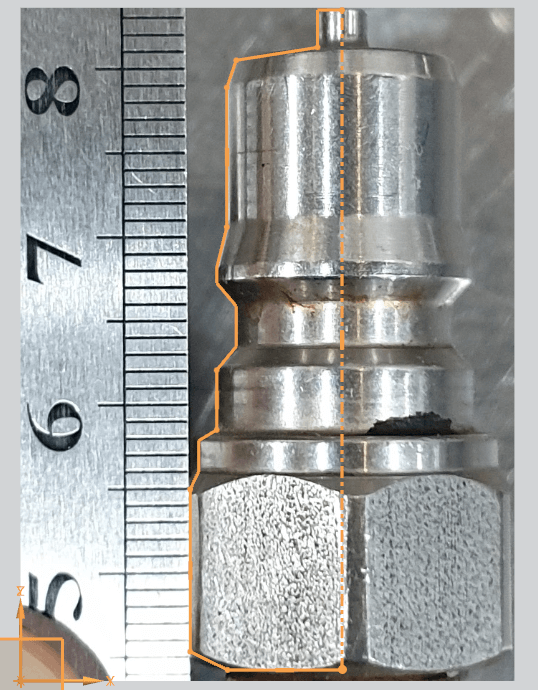

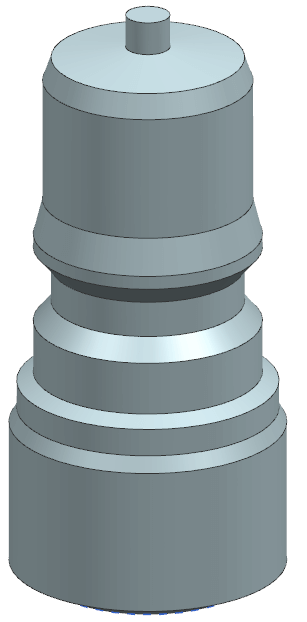

Take, for example, this quick release connection:

We didn’t have a 3D model from the supplier for it and needed to check it would fit correctly in an assembly.

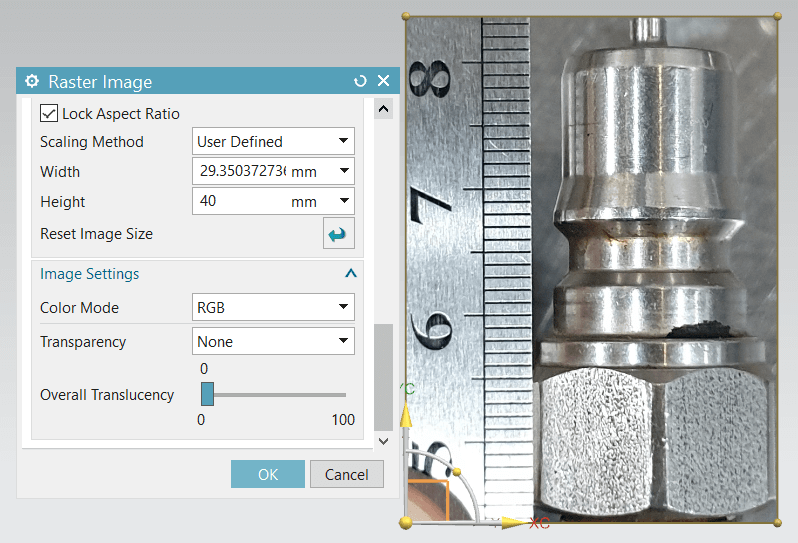

We can import the picture into the CAD model. Using Siemens NX, this is done using the Raster Image tool.

You might be wondering why there is a ruler placed next to the component for the photo.

This allows you to define how large the picture is in CAD, so you end up with an accurate representation of the component. The picture is cropped to 40 mm on the ruler, so the height of the raster image is 40 mm.

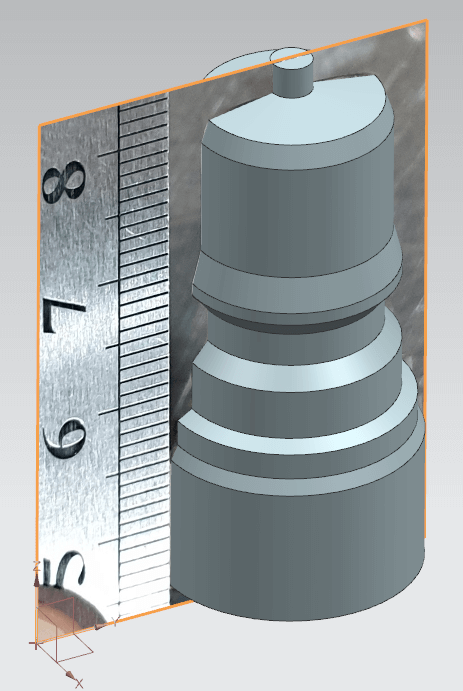

We can then sketch directly onto the picture to create the model. This is only for a rough representation so a quick sketch is all that is needed.

Now all we need to do is revolve the sketch:

We end up with a model we can use for our needs.

Very cool.

Another way a camera can be used is for photogrammetry.

If you’ve never heard of photogrammetry before, this will seem like magic.

Photogrammetry is essentially where you take lots of pictures of an object at different angles and distances. These pictures can then be compiled in software that pieces the pictures together to produce a 3D model.

If you do not have the money or resources for a high end 3D scanner, photogrammetry may be the answer.

For all of the examples listed above you don’t have to have a fancy camera. A smart phone with high resolution and slow motion features is sometimes more than enough.

2. 3D Connexion SpaceMouse

A Spacemouse, or “Spaceball” is an essential engineering tool if you use CAD a lot.

This little device will help you orientate and display a model exactly how you want it.

Gone are the days of holding down a keyboard key and simultaneously holding down the mouse to move the view of a model.

Instead, the Spacemouse can rotate the view by pushing, pulling, rotating and moving the black plastic shown below:

You may find getting used to it difficult.

This is normal.

If the model shoots off into space at the slightest touch, change the sensitivity so it is slower. If the model rotates too slowly, increase the speed settings.

Play around with the settings and just keep using it on a daily basis.

Some packages come with 3D exercises, such as moving around Tetris-style blocks, to help you get used to it.

And then one day, you will wonder how you ever did without it.

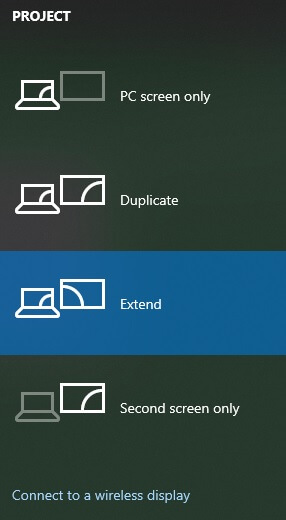

3. Multiple Monitors

Having more than one monitor can be a game changer if you sit in front of a screen all day.

Not only is there literally more space for you to use, having two monitors allows you to have two applications displayed at the same time.

This stops the need for flipping between applications on just one screen.

If you don’t have two monitors but instead have a laptop screen and one monitor, consider investing in a laptop stand to act as a second monitor.

Once you have connected your monitor to your laptop, change it from ‘Duplicate’ to ‘Extend’.

To do this, if you are on Windows 10, hit Windows Key + P to pop up the project bar on the right hand side.

After clicking ‘Extend’ you will be able click and drag applications between the monitor and laptop, unlocking a very helpful way of working.

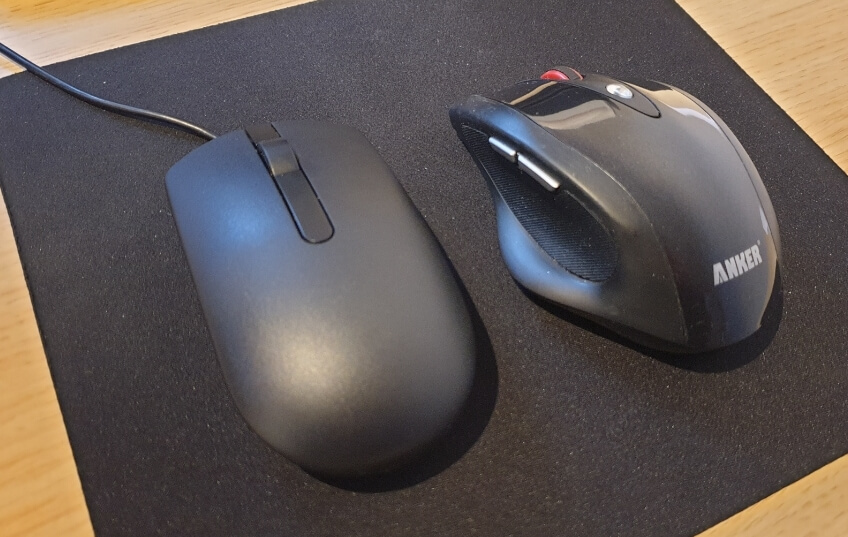

4. Gaming Mouse

Thought a gaming mouse was just for the hardcore gamer who counts FPS?

Think again.

Gaming mice are designed for extra comfort and will hands down beat the standard low-budget company mouse you’re given.

Where this type of mouse comes into it own, though, is it’s ability to be customised.

Gaming mice come with extra buttons, and these buttons can be used to help your day to day engineering.

Use Ctrl + C and Ctrl + V a lot?

Why not associate these commands to the gaming mouse so you don’t have to touch the keyboard to copy and paste?

Change the view to isometric a lot in CAD?

Change the settings in the CAD package so you can now change to isometric in one click.

Pro tip: Consider using a wireless mouse if you give a lot of presentations. This will save you from having carry lots of leads everywhere every time you present.

5. Mechanics Mirror

Mechanics mirrors are very similar to the ones you see when you go to the dentist.

They are very useful for looking in awkward places or for inspecting around corners.

For example, in an intricate electrical assembly a small mechanics mirror can help you check the components are sitting correctly.

Larger variants are also available, ones that are big enough to move around on the floor and see underneath car chassis.

This can be a very useful physical tool for an engineer.

6. LED Torch

Having a small LED torch to hand can be very helpful.

For inspecting small areas, you can’t go wrong with a flashlight that fits on your keyring. It’ll stop you using the flashlight on your phone and wasting charge, yet always have one to hand.

If inspecting a larger area (for example HVAC systems) a large rechargeable torch will be required if you are surveying all day.

If you deal a lot with plastics, a torch can be used to check the surface finish by shining it on the product.

7. Calipers

Calipers are an engineering staple.

They are useful to have on your desk as a sanity check when using CAD software. Is 10 mm really enough clearance? A quick check with a caliper offers immediate validation.

We would personally recommend getting a cheap digital one for day to day use – one that you also wouldn’t mind scribing with.

And if you have the money, it’s wise to invest in a good quality analogue set of calipers.

The slow refresh rate associated with digital calipers makes analogue the winner here.

Digital calipers can also give an incorrect reading if the battery is low, so that’s something to look out for.

You could also opt for a dial caliper. On this, a circular dial shows an instant reading to the fraction of a millimetre (or inch), without having to read a Vernier scale.

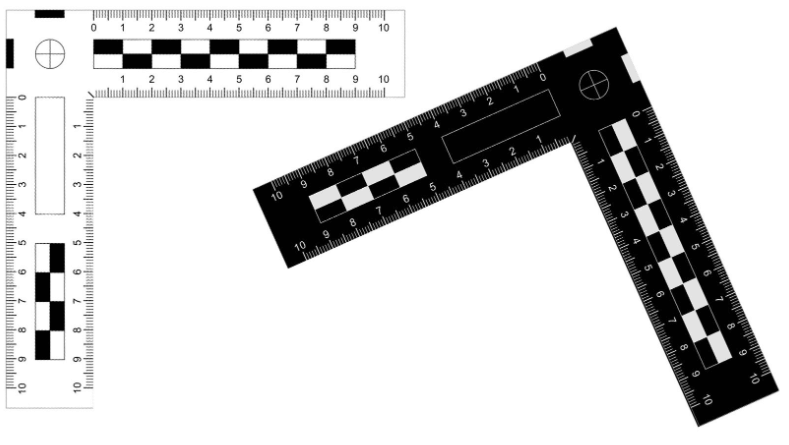

8. Rulers

An engineer shouldn’t be without a ruler by their side; it’s one of the most underrated engineering tools.

Having a quick way to check physical measurements is useful and comes up surprisingly often.

We’d go for a clear ruler for the desk and a metal ruler if on site.

If you want to go a step further you can buy a forensic ruler, the type used in crime scene investigations. They’re not that expensive and can be very useful when taking pictures of components.

Source: Desertcart

If using photogrammetry, a black and white ruler is good for acting as a target for the object you are capturing.

9. Gorilla Tape

Source: Amazon

Some engineering tools needn’t be complicated.

Gorilla tape is a stronger equivalent to duct tape. It is useful to temporarily stop things moving when they shouldn’t be.

10. Sticky Tac

For loads which are less than Gorilla tape applications, Sticky Tac is your friend.

Very useful for holding smaller pieces for short periods of time.

Examples include: holding test fixtures together, holding small parts under an inspection microscope and steadying parts that are about to be soldered.

11. Smartphone

A smartphone can be used for many items on this list and much more.

Apps can be downloaded to give you access to engineering tools that help you with everyday tasks. Apps for belt tension, sound level, vibration monitoring, surface levelling, navigation, time measurement, augmented reality, distance measurement, GD&T, image searching… You’ve also got the wealth of knowledge that is the internet at your fingertips.

When taking pictures, a smartphone be more useful than a large camera as the tiny lens can take pictures through small holes.

12. Stroboscope

A stroboscope is another tool that can be downloaded as an app to your smartphone.

A flashing light is great for when dealing with fast moving equipment.

For example, say you want to inspect a motor shaft that is rotating at high speed but you can’t turn off the machine.

Using a stroboscope and changing the flash frequency to match the rotation of the torque limiter will make it look ‘frozen’ in time.

When you first see it it’s like magic – a great way to check a still picture of the machine whilst it’s in action.

The same can be used for Process Engineering. Using a stroboscope on extrusion can show how the plastic is formed, change the strobe frequency and the product will look like it’s forming in slow motion.

13. Thermal Camera

A thermal camera is a useful tool for diagnosing failures as quite a lot of failures involve heat. Shorted electrical components will cause heat, which will show up on the thermal camera.

Another example is that faulty bearings tend to cause friction which can cause heat. Using a thermal camera will quickly show you which bearing is faulty by the hotspot on the screen.

This also provides a record of the temperature gradients which is useful for future reference.

14. Anatomical Measuring

You may have heard the saying “In a pinch, from knuckle to nail equals an inch”.

That is to say, roughly speaking, the distance between your thumb’s knuckle and its nail equals one inch.

May not be strictly true but the principle holds true.

If you know what length your limbs are, you always have a quick way of checking the dimensions of something.

For example, say you know that your hand span is 200 mm. You now have a way of measuring objects that don’t need high precision.

This can be taken one step further.

If you know what your walking pace is and have a stop watch to hand, you can use this info to calculate the distance of where you have just walked. Simply multiply your walking pace speed by the time it took you to walk it.

If you need to know the area of a site, you could walk the length and width of the space and multiply these together.

Useful for when you need answers fast but don’t have the equipment available.

Who knew that you couldn’t buy some engineering tools?

15. Multimeter

A multimeter is one of those engineering tools you should own no matter what type of engineer you are. It’s a quick way to check your electronics are still in order and will help you fault-find components at home too (such as checking fuses).

Make sure you know what you’re doing before messing around with electricity.

Invest in a high quality one and it should last you years; buy a second hand one if they are too expensive.

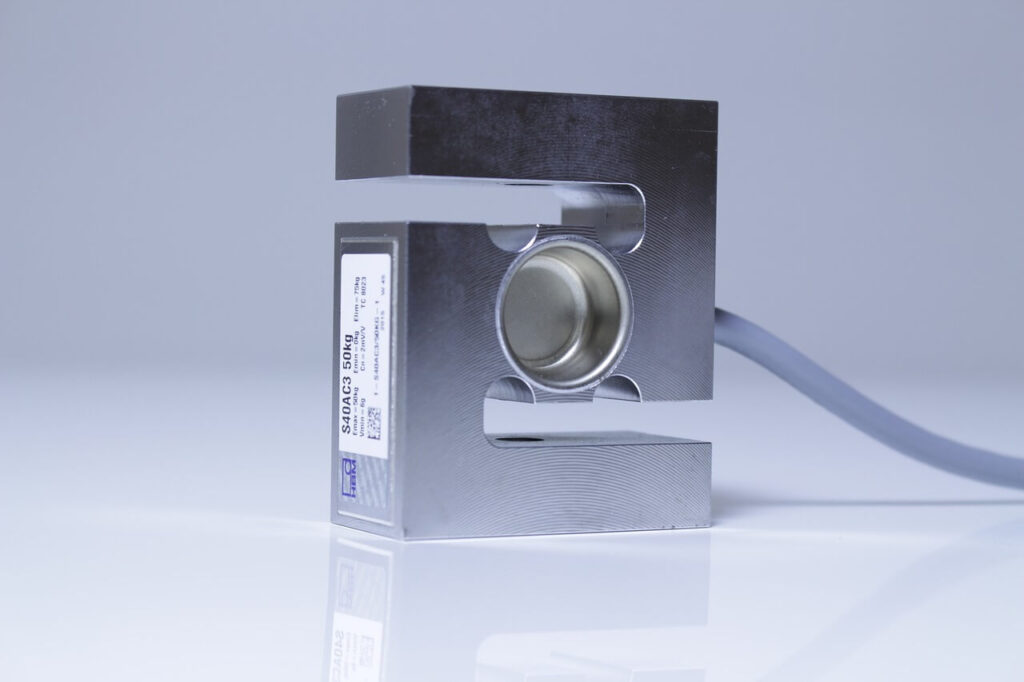

16. Load Cell

A load cell is used for measuring loads. It is a great way to record numerical data for tension, compression, pressure, or torque experienced.

A force gauge is a useful device for measuring different forces experienced.

17. Pens

Some engineering tools are very complex, not this one.

Pencils and pens are simple tools but are essential for engineers.

We love the Uni Pin Fine Line for sketches that are waterproof and fadeproof.

Comparatively, a lot of engineers swear by erasable pens such as Frixion.

18. Calculator

This one is a must.

Whether you have a graphical TI-89, a cheap Casio or even Windows Calculator – this needs to be available at all times.

19. 3D Printer

Having access to a 3D printer will step up your engineering level.

It’s great to able send a CAD model to a printer and physically check it before you commit to a design.

This can save lots of headaches later if you are unsure at the design stage.

We recommend getting your own one for home so you can tinker and learn another skillset. 3D printers seem to be getting cheaper and it really does give you freedom to design whatever you want and see it in the real world.

20. Laser Scanner

A handheld laser scanner is perfect for scanning small components and converting them into a 3D model.

Reverse engineering tools (such as surface modelling) are often required, as scans are not always 100% and will need some cleaning up.

On the larger scale, a laser scanner can be used to create a 3D model of a whole building. This is useful for Civil Engineers scanning a client’s site.

This also has it’s uses for Mechanical Engineers, for example if you need to check whether equipment will fit on a customer’s site.

Not only that, it has the ability to be used for taking measurements without having to physically travel to the site.

Additionally, laser scanning can lead into virtual reality applications, too.

21. Knee Pads

This goes without saying if you have to work lower down on assemblies. Save your knees!

22. Paper

Paper is underrated in a digital world. It’s one of those tools that engineers forget about.

It’s great for getting concepts down in the early stages of design.

For us, concepts start on paper before even touching CAD. This can save a lot of time as it’s generally quicker to sketch on paper than to make a model using CAD.

Paper is also great for explaining to your peers what’s in your head. Practise sketching concepts daily – it’s a skill that’s definitely worth having as an engineer.

Can’t sketch? A good place to start with is cartoons. Cartoons are designed to be quickly recognisable and use basic shapes.

Get yourself some nice lined and graph paper.

It’s also great for journaling and organising your life.

Thought paper notes were just for students? Think again.

23. Thinkpad

Thinkpad laptops are used as standard in most industries and for good reason too.

These things are built like tanks.

They are very robust, useful as engineers are usually in places where equipment needs to survive a beating.

There are so many different ports on the Thinkpad. This means you won’t be caught out by not having the wrong dongle.

They are reliable, no nonsense laptops.

See how you get on with one, you might not go back!

Now We’d Like to Hear From You

There you have it: 23 engineering tools you should know about.

Now we’d like to hear what you have to say:

Did you learn any new tools from today’s post?

Or maybe you have certain engineering tools that you couldn’t be without.

Either way, let us know by leaving a quick comment below.

5 thoughts on “23 Engineering Tools You Should Know About (Physical Tools)”

Great article. The engineering tool I couldn’t be without is my 3D printer. It’s perfect for turning ideas in my head into something I can hold.

Hi Sam, thanks for your comment!

Hi,

When I measure dimension on-site, I usually bring pen, paper, Vernier caliper, measuring tape and thread pitch gauge if necessary. Sometime I use spring caliper (inside/outside/divider) and ruler. After taking dimensions, I usually go straight to CAD. But for some reason, I draw manually by hand. I use simple tool like mathematical instrument set.

Thanks for your insight Maaruf!

Thanks, this is great. I also use a tape measure often as an engineer.

Thanks for the article!